AGTEKS

AGTEKS was founded in 1992 as a textile machinery manufacturer in Istanbul. As manufacturers have required higher quality yarn for higher quality garments, AGTEKS has risen to the challenge of researching and developing solutions for economical and functional products for the yarn industry. In keeping with the research and development objective of highly qualified and experienced engineering staff, AGTEKS is one of the fastest developing companies in the world. Our team continually implements many new twisting and sensing solutions to service the textile industry while working with direct contacts in the market, universities, renowned experts and research institutes worldwide. Through the release and installation of these technologies, AGTEKS continues to produce the most innovative and versatile twisting and covering machines in the market. AGTEKS’ new line of industrial sensing solutions keeps with their solid reputation in introducing previously unavailable solutions and meeting market demands and requirements.

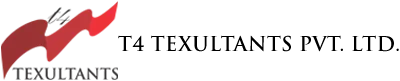

DirecTwist

DirecTwist 2B6

You can perform your twisting and covering processes in the fastest way with your staple fiber yarns and express your creativity at the same time.

Thanks to its touch screen, it is possible to set the parameters you would like to run. You can produce the combinations you dream of with the highest level of precision in this machine equipped with the latest technologies.

You can quickly get your final yarns by placing your bobbins at the bottom of the machine. "DirecTwist-2B6" is very suitable for use in factories, research laboratories, and showrooms thanks to its compact design.

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum twisting speed | Up to 18,000 twist/minute |

| Maximum twist value | Up to 2,000 twist/meters |

| Maximum production speed | Up to 200 meters/minute |

| Total twisted yarn thickness | 100 Nm to 1.8 Nm (~90 Denier to ~5,000 Denier) |

| Take-up cone size | 170 mm length conical cone |

| Max. take-up cone diameter | 220 mm |

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | 8 sets optical sensors and optional capacitive sensor for elastane |

DirecTwist ®2C10"

You can twist and cover your thick yarns in one operation. Possible to use many thick yarns together with its design inspired by the C6" machine. You can set all your parameters on the touch screen and monitor many parameters such as the remaining production time.

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum twisting speed | Up to 10.000 twist/minute |

| Maximum twist value | Up to 1.000 twist/meters |

| Maximum production speed | Up to 200 meters/minute |

| Total twisted yarn thickness | 100 Nm to 0.5 Nm (~90 Denier to ~20.000 Denier) |

| Take-up cone size | 290 mm length conical cone or cylindrical cone |

| Max. take-up cone diameter | 260 mm |

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | On optional external creel. Wiring is provided for custom creels |

DirecTwist® 2D6

You can perform twisting and covering processes with your technical yarns such as carbon, glass, metal, aramid, etc. It is also possible to use any type of yarn. Thanks to its high-tech design, you can produce your yarn from the first meter to the last meter. You can become the new star of the technical textile industry by meeting the world’s best twisting machine.

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum twisting speed | Up to 8,000 twist/minute |

| Maximum twist value | Up to 1,700 twist/meters |

| Maximum production speed | Up to 82 meters/minute |

| Total twisted yarn thickness | 100 Nm to 0.9 Nm (~90 Denier to ~10,000 Denier) |

| Take-up cone size | 160 mm length double-flanged bobbin |

| Max. take-up cone diameter | 160 mm |

| Max. yarn plies to be twisted | Unlimited |

| Yarn break sensors | On optional external creel. Wiring is provided for custom creels. |

Yarn Scanner

Quality Eye

Quality Eye is the quality control unit for detecting structural defects of yarn in twisting and winding machines. These sensors, which can measure up to 100 meters per minute, instantly measure and report yarn quality.

Quality Eye detects and reports all quality issues such as yarn breakage, thickness variation, slub, lump, and splice recognition. It can measure the length, thickness, hairiness, and tension of the yarn. With its user-friendly operator panel, it can also send a “Stop” command to the machine when necessary.

Technical Specifications

| Parameter | Specification |

|---|---|

| Sensor Type | Photo Diode |

| Pixel count | 1 |

| Renovation | None |

| Axis | No axis |

| Dtex value | Immeasurable |

| Sensor signal | Relative change |

| Pollution level | None |

| Yarn speed | Up to 2,500 meters/minute |

Digital Dropwire

Digital Dropwire is an intelligent digital lamella system developed as an alternative to the traditional mechanical lamella system in warping and rope opening processes. It provides real-time tracking of yarns online during operation.

Digital Dropwire detects the number of yarns in the warping process and automatically stops the system when any yarn breaks, ensuring high efficiency and reduced downtime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Technology | High-speed scanning sensor |

| Sensor resolution | Up to 600 dpi |

| Scan length | Up to 600 cm |

| Detection speed | 6,000 lps |

| Defect detection | Yarn break, yarn defect |

| Contact | Ethernet or Wi-Fi |

| Output | 2 pcs NPN, open collector, max 50 mA |

| Recording | Defect time, defect location, machine number, defect name |

Smart Guide

Smart Guide is a system that measures 360-degree tension of yarns with smart bead technology. It allows the use of creel exits or in all passageways of the yarn. It can also send a “Stop” command to the machine when necessary.

There are 3 different models in Smart Guide

- Model A: 0-300 cN, precision ± 5 cN

- Model B: 0-500 cN, precision ± 5 cN

- Model C: 0-1000 cN, precision ± 5 cN

TensionBar

TensionBar is a system that can measure and report the tension of each yarn in multiple yarn working areas. If necessary, it can also send a warning and “Stop” command to the machine.

There are 3 different models in Smart Guide

- Model A: 0-300 cN, precision ± 5 cN

- Model B: 0-500 cN, precision ± 5 cN

- Model C: 0-1000 cN, precision ± 5 cN

Spinning Automation

QBARPro-Cam

QualityBar is an online fabric quality control system with high-resolution flat scanner sensors that simultaneously detect and classify visual defects on fabric. Unlike camera-based systems, scanners provide homogenous lighting and capture from all angles, eliminating the side blindness problem of cameras.

QualityBar applies artificial intelligence and deep learning algorithms, achieving more than 95% accuracy even for the smallest defects. With selectable resolutions of 300 or 600 dpi, and the ability to work up to 60 meters/minute, it ensures reliable, real-time quality monitoring across a wide range of fabrics.

Technical Specifications

| Parameter | Specification |

|---|---|

| Technology | High-speed scanning cameras |

| Scanning Width | Up to 6 meters |

| Scanning Speed | 50 meters/min |

| Defect Detection | Point, Horizontal and Vertical |

| Yarn Type | Knitting, Weaving |

| Signal Input | 2 pcs External Input |

| Signal Output | PNP, 1 pc dry contact role output, alarm |

| Program Control | Multi-core embedded deep learning computer control |

| Integration | ERP |

| Recording | Defect Time, Defect Location (X,Y), Defect Size, Measurement, Defect Name, Defect Picture, etc. |

Finishing Bar

Finishing Bar is the system that detects online the defects on the fabric and determines their locations and type with cameras. The cameras make the detection process with the help of light sent from stable light sources.

Technical Specifications

| Parameter | Specification |

|---|---|

| Technology | High-speed scanning sensor |

| Camera Resolution | Up to 8K |

| Scanning Width | Up to 6 meters |

| Scanning Speed | Up to 450 meters/minute |

| Detection Speed | 26,000 lps |

| Defect Detection | Fabric defect, weft defect, warp defect |

| Fabric Type | Woven, nonwoven or knitted fabric |

| Program Control | Graphic display on PC |

| Recording | Defect time, defect location (x,y) on the fabric, machine number, defect size, defect picture, defect name, etc. |

Shade Lab

Shade Lab is a desktop spectrophotometer that measures the color values of textile materials.

Shade Lab, Unlike conventional spectrophotometers, makes the most accurate measurements on pile surfaces and in-grained structures.

Shade Lab, makes color measurements based on the recommendations and standards of the International Commission on Illumination [CIE-Commission Internationale del’Eclairage] by means of a spectrophotometer.

Technical Specifications

| Parameter | Specification |

|---|---|

| Technology | Monolithic structured high precision micro spectrometer |

| Spectral Sensitivity | =< 3 nm |

| Measurement Accuracy (Delta E) | =< 0.05 |

| Measurement Spectrum Range | 380 – 780 nm |

| Measurement Area | 15 mm diameter |

| Source of Light | Sunlike LED |

| Recording | Recording reference and measurement values |

ShadeBar

Shade Bar is an online quality control system that detects edge differences, color filtering, and lot differences that may occur in the production of dyed fabrics using a spectrophotometer.

Shade Bar calculates Delta E differences by measuring L, a, b values on the flowing fabric instantly. It provides benefits in terms of quality and time in subsequent production processes. The system provides continuous color control by measuring the optical reflectance values of the fabric. If necessary, it can also send a “Stop” command to the machine during detection.

ShadeBar, another pioneer of the Industry 4.0 breakthrough in the textile industry, can send calculated data to computer memory, cloud storage, or web provider systems. It performs color measurements in accordance with the recommendations and decisions of the International Commission on Lighting (CIE - Commission Internationale de l’Eclairage).

Technical Specifications

| Parameter | Specification |

|---|---|

| Technology | High precision spectrometer |

| Spectral Sensitivity | <= 3 nm |

| Scanning Speed | 100 measurements/second |

| Measurement Spectrum Range | 380 – 780 nm |

| Defect Detection | Wing differences, color filtering |

| Communication | Ethernet or Wi-Fi |

| Recording | Defect time, defect location (x,y) on the fabric, machine number, defect size, defect picture, defect name, etc. |

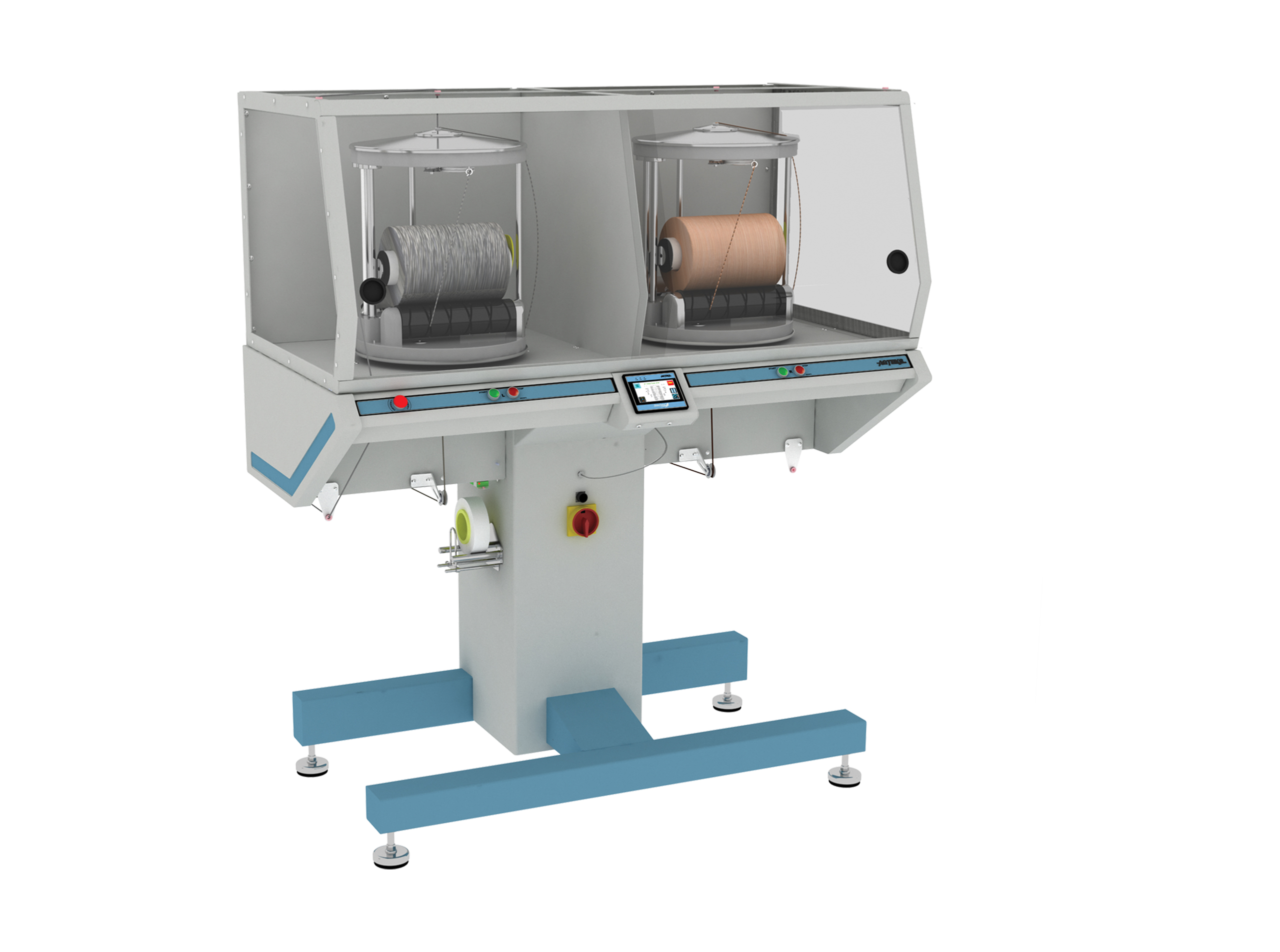

Intelliwinder

IntelliWinder

IntelliWinder enables yarns of flat knitwear to be recovered with detection and learning logic for maximum efficiency. It can unravel up to 6, 8, 10, or 12 ends simultaneously.

Technical Specifications

| Parameter | Specification |

|---|---|

| Number of unraveling units | 6 | 8 | 10 | 12 |

| Winding speed | 0–300 meters/minute (all systems adjustable individually) |

| Programmable grouping modes | Different grouping methods for different numbers of ends |

| Yarn tension adjustment | Operation panel, ultra-sensitive, precise servo-regulator |

| Individual indicators on each system | System cancel, tension, sense, overload, yarn flow rate |

| Fabric fixing | By special ball-point needles allowing easy fixing of knit fabrics |

| Automatic stop | Yarn breakage, entanglement, bobbin limit, misguided yarns, etc. |

TechnoWinder

TechnoWinder allows winding yarns on any bobbin to double-flanged bobbins precisely and quickly.

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum Speed | Up to 680 meters/minute |

| Take-up Bobbin size | Up to K160 double-flanged bobbin |

| Feeding bobbin weight | Up to 5 kg (11 lbs) |

| Supply bobbin size | Any size |

| Yarn break sensors | Optical sensors |

| Automatic stop | Yarn break, emergency |