Perfect

A company created by Technocrates Four decades ago. PERFECT continues to be driven by a clear vision for excellence in technology and engineering. This single minded pursuit of uncompromising quality standards and continuous innovation has catapulted PERFECT into the international market, making it the choice source of leading multinationals in the Global Textile Arena.

PERFECT’S ability to integrate technology, processes and customer requirements into ingenious solutions has resulted in delivering the machines with highest efficiency at a very economical price.

Roll Shop Maintenance Machine

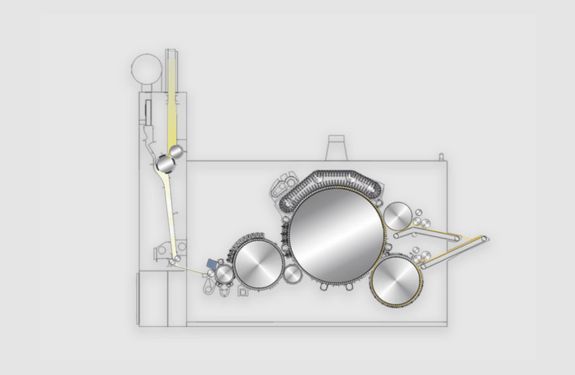

Cot Grinding Machine

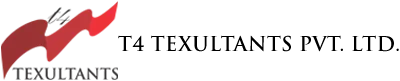

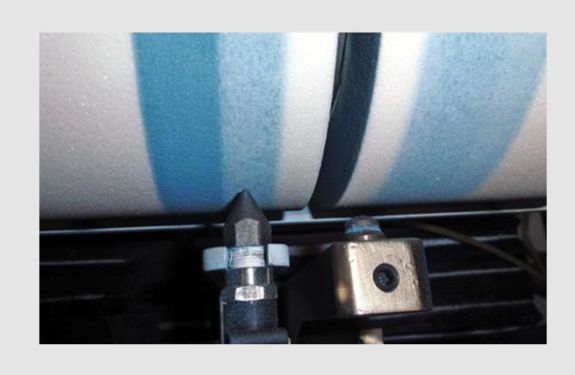

The Fully Automatic Cot Grinding Machine is engineered for precision grinding of top rollers from any make of Ring Frame and Speed Frame. Designed for reliability and accuracy, it delivers consistent surface finish and performance that meets international quality standards.

Fastest Cot Grinding Machine in the World

Product Highlights

- Output: Up to 600 arbours / Hr (1200 cots / Hr)

- Surface Finish: Ra ≤ 0.5 µm

- Integrated Systems: Auto measuring system and auto dressing of grinding stone – no operator intervention required

- Automation: Easy loading, automatic feeding, and large storage capacity

- Precision Control: C. Servo motor positions grinding stone with an accuracy of 0.01 mm

- User Interface: Touch screen display with graphical interface, multi-language support, and fault indication

- Roller Speed: Variable speed adjustment according to cot diameter

- Maintenance: Programmable automatic cleaning and dressing of the grinding stone

- Efficiency: Faster payback and equipped with a powerful dust extraction system

- Power: 7.2 kW

Working Programs

- Grinding to predetermined diameter

- Grinding to a fixed cut on different diameters

- Sorting of top rollers with or without grinding

- Programmable automatic dressing of grinding stone

Other Roll Shop Maintenance Machines

Our roll shop maintenance machines cover a wide range of grinding, checking, mounting, cleaning, and lubrication equipment for top-quality textile production and maintenance.

1. Automatic Cot Grinding Machine – ACG 2

2. Twin Head Twin Feeding Cot Grinder – TWG – TF

3. Twin Grinder – TWG

4. Cot Grinding Machine – BM – 1 AF

5. Cot Grinding Machine – BM – 1

6. Cot Grinding Machine – MM – 2

7. Cot Grinding Machine – SM – 3

8. Fully Motorized Cot Checking Device – FMCC

9. Cot Checking Device – CCD

10. Shore Hardness Tester

11. Cot Mounting Machine / Press – CMHY – V

12. Horizontal Hydraulic Cot Mounting Machine – CMHY – H

13. Hand Cot Mounting Machine – MCM – 4

14. Cot Mounting Pneumatic Machine – CMPT

15. Automatic UV Treatment Machine – UVT – OL

16. Ultra Violet Treatment Machine – UVTM

17. Automatic Arbour Greasing Machine – ARG

18. Hand Operated Greasing System for Arbour – HARG

19. Automatic Arbour Flushing Machine – ARF 1

20. Automatic Arbour Flushing Machine – ARF 8

21. Spindle Lubricating Machine with 3 Tank – SL3

22. Ultimate Flyer Cleaning Machine – HOT CLEAN HP20

23. Hydraulic Fluted Roller Truing Machine – FRTH

24. Manual Fluted Roller Truing Machine – FRTM

25. Clearer Roller Cleaning Machine – CRCS – AF

26. Clearer Roller Cleaning Machine – CRCS

27. Roving Stripping & Opening Machine – ROS

28. Roving Waste Opener – RWO

Card Room Maintenance Machine

Automatic Flat Grinding Machine – AFG 3

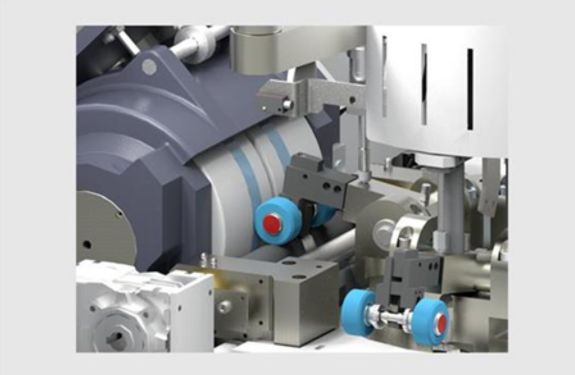

The Automatic Flat Grinding Machine – AFG 3 from Perfect Equipments is a precise, efficient solution for card-room flat maintenance. Available in two models (for 37–40″ and 37–60″ flats), it grinds up to three flats simultaneously using high-quality ceramic rollers or emery fillets. The machine features a centralized lubrication system and powerful dust extraction to ensure smooth, reliable operation.

Product Highlights

- Available in two models for flat lengths of 37"~40" & 37"~60"

- Precise grinding of one or three flats simultaneously

- Choice of grinding media: Ceramic roller or Emery fillet

- Centralized lubrication system

- Efficient dust extraction system

- Power: 1.87 kW

Other Card Room Maintenance Machines

Our card room maintenance machines are designed for precise and efficient maintenance of flats, rollers, and wires to ensure smooth carding operations and prolonged machine life.

Machines List

1. Flat Clipping Machine – PFC 4

2. Flat End Milling Machine – FEM 2

3. Roller Wire Mounting Machine – RMM 1

4. Butt-Welder

5. Wire Unwinding Machine

6. Reciprocating Stone Grinder

7. On Card Flat Grinding Roller – OCFG 1

Spinning Automation

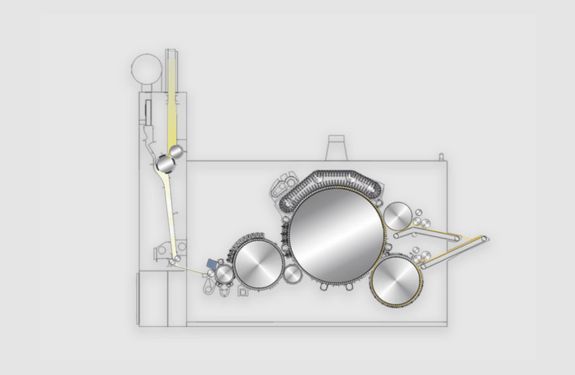

Blowroom Line for Cotton

Product Highlights

- Compact line for production output up to 800 kg/h

- High cleaning efficiency with low nep generation

- Synchronised feeding with cards by advanced PLC control

Blowroom Line for Man Made Fibres

Product Highlights

- Better opening of bales

- Synchronised feeding with cards by advanced PLC control

- Option with flat magnet over inclined lattice

Card 1000

The Card 1000 from Perfect Equipments is a robust, high-capacity carding machine engineered for both cotton and man-made fibers. It features the largest carding area in its class (2.91 m² for a 1000 mm width), ensuring high productivity and consistent fiber processing.

Product Highlights

- Largest carding area of 2.91 sq. m (for any 1000 mm width Card)

- 37 flats in working position

- Licker-in options: Single or Triple to suit any type of material

Applications

- Ring & open-end spinning of cotton & man-made fibers

- Card 1275 BSD

- Bale Opener

- Heavy Particle Separator with Bend Magnet - PHPS

- Bend Magnet - PVM

- Opti Cleaner

- Opti Mixer

- Fine Opener - PF

- Dust Separator - PDS

- Cage Condenser - PCC-50

- Conveyor Inspection Table - PCT-71

Recycling

Hard Waste & Fabric Opening Line (PRT 1000)

The PRT 1000 is a robust recycling solution designed specifically for opening and processing spun-yarn and fabric waste, including knitting and hosiery materials. With a configurable capacity ranging from 60 kg/h up to 240 kg/h, the line can be tailored to suit space constraints and operational needs. It offers flexibility in placement and includes all essential mechanisms for converting hard textile waste into reusable fiber. Ideal for mills aiming to enhance sustainability and reclaim value from waste fabrics.

Product Highlights

- Opening line can be configured for 60 kg/h to 240 kg/h capacity

- Full-fledged line to handle all kinds of hard waste made of spun yarns

- Flexible placement of line as per space available

Applications

- Opening of spun yarn waste

- Knitting hosiery cloths

Cotton Waste Recycling Line

- Gentle cleaning

- Line can be synchronised with direct feeding of cotton waste from compactors using silo

- Very high cleaning efficiency for dropping cotton waste

- Lines available for feeding 5 ton, 10 ton & 15 ton per day capacity

Cutter - ECO-300 & ECO-500

- Rotary cutter with three blades

- Robust & sturdy structure

- Bigger diameter feed roller with pneumatic loading

Cutter Blade Grinder - PBG

- Adjustable angle of grinding

- Automatic traversing of grinding stone

Cotton Waste Recycling Line

Product Code: Cotton Waste Recycling Line

The Cotton Waste Recycling Line is designed for gentle cleaning and high-efficiency processing of cotton waste. It can be synchronized with direct feeding from compactors using a silo, ensuring smooth and continuous operation. Lines are available for capacities of 5 ton, 10 ton, and 15 ton per day.

Product Highlights

- Gentle cleaning of cotton waste

- Line can be synchronized with direct feeding from compactors using silo

- Very high cleaning efficiency for dropping cotton waste

- Lines available for feeding 5 ton, 10 ton & 15 ton per day capacity

Applications

- Cotton recycling

- Surgical applications

Other Recycling Machines & Options

- Cutter – ECO-300 & ECO-500

- Cutter Blade Grinder – PBG

- Magnetic Conveyor Roll Table

- Evener Feeder with 2 Condensor

- Six Chamber Cleaner with Feed Lattice

- Various Options for Feeding

- Feed Trunk

- Micro Fibre / Trim Opener

- Double Roll Trim Opener – PDRTO 1500

Card 1275 BDD

Product Code: Card 1275 BDD

The Card 1275 BDD is designed for cotton and synthetic spunlace lines, offering high productivity and efficient web formation. Ideal for nonwoven and surgical applications, it ensures consistent output up to 40 GSM.

Product Highlights

- Card for cotton/synthetic spunlace lines

- Web output up to 40 GSM

- High productivity output, optimized for spunlace lines

Applications

- Nonwoven

- Surgical

Card Room Maintenance Machine

Automatic Blending Line

Automatic Blending Line for Cotton, Synthetic, Blends, Nonwoven, Recycling & Surgical cotton material

Product Highlights

- Automatic weighing & mixing of 2 or more different components

- High accuracy of blend percentage

- Production output depends on blend proportion up to 750 kg/h

Card 1275 BDD

Product Code: Card 1275 BDD

The Card 1275 BDD is designed for cotton and synthetic spunlace lines, offering high productivity and efficient web formation. Ideal for nonwoven and surgical applications, it ensures consistent output up to 40 GSM.

Product Highlights

- Card for cotton/synthetic spunlace lines

- Web output up to 40 GSM

- High productivity output, optimized for spunlace lines

Applications

- Nonwoven

- Surgical