Drive Service Site Assessment

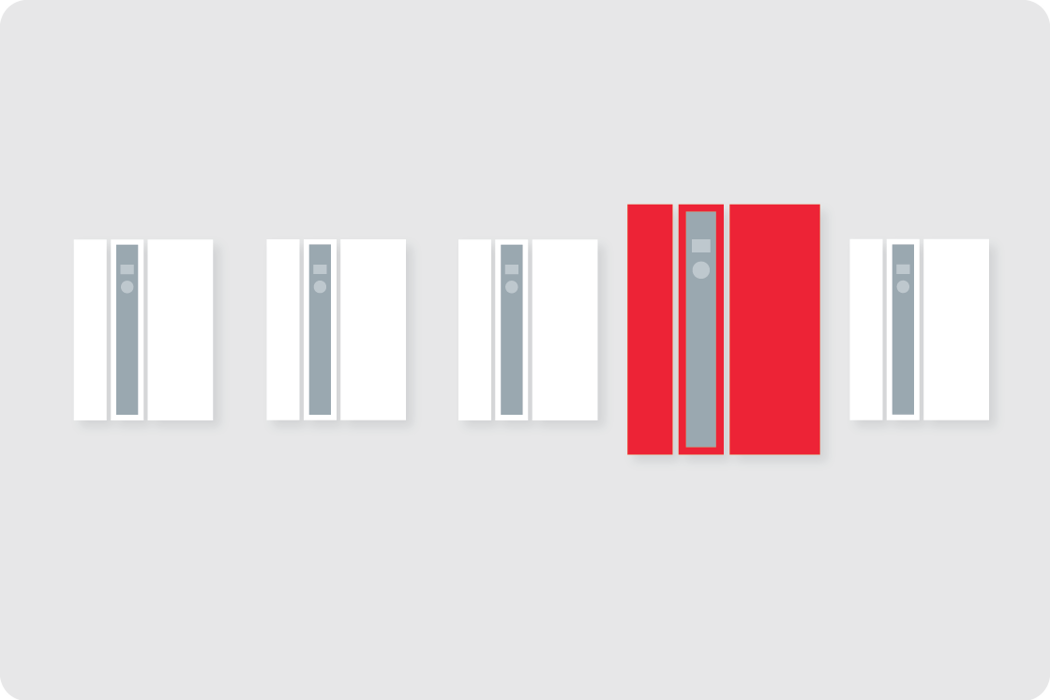

Did you know 1 out of 5 AC drives are at risk of failure?

Minimize unexpected costs and downtime by ordering a Drive Service Site Assessment.

Drive Service Site Assessment is a service for asset management that includes a complete onsite survey and risk analysis of your whole installed base of AC drives.

Our Danfoss experts look at every drive onsite to record the asset condition, the criticality, and the lifecycle status. Based on these parameters, we calculate a risk result for every AC drive and make recommendations for the product's lifecycle journey accordingly.

The full analysis is then summarized in a customized and detailed report for you. On this basis, you can build a tailored plan for future maintenance or retrofits to the new generation together with our experts.

Features and benefits

Complete overview of your installed base of AC drives on-site

- See the latest lifecycle status of each Danfoss AC drive

- Asset criticality evaluation

- AC drives condition evaluation

Detailed site analysis report

- Asset risk analysis

- Risk mitigation plan

Interactive expert recommendation

- Highlight high-risk AC drives

- Identify potential for improved energy efficiency

- Selection of services from well-designed Drive Service portfolio

- Optimized planning ensuring highest productivity with lowest cost impact

T4 Energy Solutions

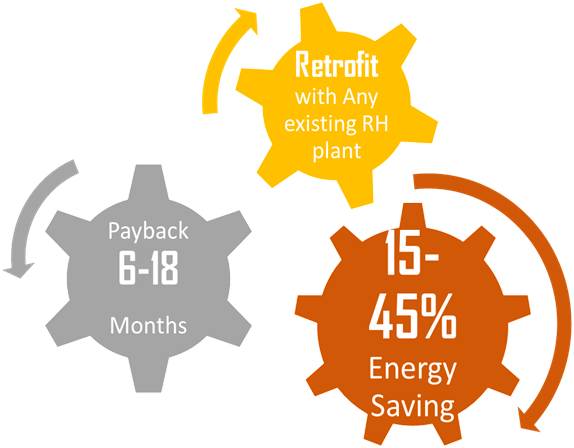

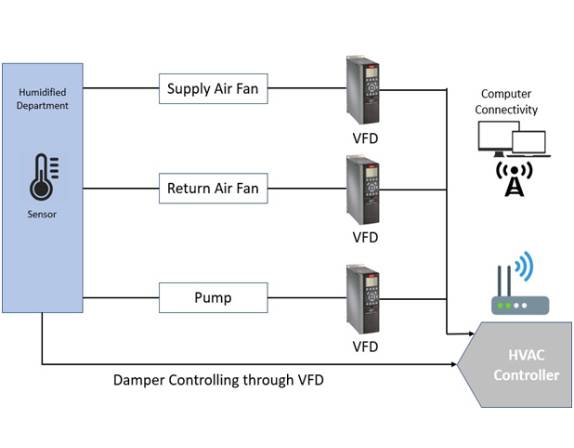

H-Plant HVAC Controller

HVAC control system helps you automate the conventional RH plant. While saving considerable energy, we ensure the Productivity and Quality of the product is maintained through intelligent communication of fan speed and climatic conditions.

By incorporating an HVAC Controller for the Humidification Plant, the required conditions of the department will be maintained uniformly throughout the year. The supply air fan, exhaust air fan, and pump operation will be controlled automatically, and their capacities will be optimized to the required level.

The energy consumption of humidification plants can be reduced by 15% to 40% of the total humidification power in the existing condition.

Benefits

- Logic Control of dampers & speed of fan & Pumps to maintain accurate climatic condition in the department throughout the year.

- Controlling of Dampers for recirculation in case of extreme weather conditions.

- Unique Control of Moisture through Wet bulb temperature provides not only favourable climate to materials but to comfort to human also. This improves the labour productivity.

- Online Monitoring & recording of RH , temperature, Damper position & power etc all the time through central computer.

Pneumafil Controller System

PneumafilControllerSystemoptimises running of pneumafil motorand suction pressure based on Closedloop feedback system according to thenumber of end breakage at any giventime.

Key Features

- Maintains optimum pressure constantly with accurate, reliable pressure sensor.

- Pressure increases automatically to meet demand during start-up and avoid higher-end breaks.

- Generally, in long Ring frame machines, power saving of 1–2 units per hour is being achieved.

Benefits

- Energy saving up to 25–40% with payback less than 1 year.

- Suitable for any count and material.

- Better power factor.

- Direct pressure setting.

Spinning Pully Conversion

Flat pulley / timing belt conversion helped to improve productivity, quality of end products and to save considerable amount of energy.

Key Features

- Continuous curve manipulation and smooth speed change even with few points on the speed profile.

- Programmable smooth acceleration/deceleration during start-up, stop, and doffing.

- TPI monitoring, alarming, and tripping.

- Versatility of production/speed/count increase – speed pattern up to 24 steps.

- No extra energy saving observed, but these changes can yield up to 5% production gain.

Climate Solutions for Heating

Danfoss Climate Solutions for heating engineers technologies that enable the world of tomorrow to do more with less. We decarbonize district energy networks by making them more resilient and energy efficient. We reduce CO2 emissions in buildings and make them comfortable places to be in at the same time. And we ensure home-owners and tenants benefit from the latest smart heating technologies to heat their homes at the lowest possible costs.

Find out more about our products and solutions:

Valves

- Hydronic balancing and control

- Shut-off ball and butterfly valves for district energy

Burner Components

Heat Exchangers

- Brazed heat exchangers

- Gasketed heat exchangers

- Welded heat exchangers

Differential Pressure and Flow Controllers

Floor Heating; Ice and Snow Melting

- Electric underfloor heating

- Hydronic underfloor heating

- Ice and snow melting, frost protection

Electric Heating

Radiator and Room Thermostats

- Radiator thermostats

- Room thermostats and time controls

Stations and Domestic Hot Water

- Domestic hot water

- Villa stations

Electronic Controls

- Electronic controllers and application keys

Pumps

Smart Heating

- Smart heating

Electric Heating (Indoor/Outdoor)

- Indoor

- Outdoor

Climate Solutions for Cooling

Danfoss Climate Solutions for cooling, we engineer technologies that help you engineer technologies of today and tomorrow. We provide products and solutions for use in Food Retail, Air Conditioning, and Industrial and Commercial Refrigeration. Our comprehensive product portfolio includes valves, sensors, controls, electronics, pumps, heat exchangers, and compressors.

Find out more about our products and solutions:

Compressors

Valves

- Check valves

- Control and regulating valves

- Electric expansion valves

- Solenoid valves

- Thermostatic expansion valves

Electronic Controls

Switches

Filter Driers and Strainers

Heat Exchangers

Sensors and Transmitters

- Pressure transmitters

- Temperature sensors

Condensing Units

Sight Glasses

Appliance Controls

Spinning Consultancy Services

Our “Spinning Consultancy” services cater to both new spinning projects and existing operational mills. We provide complete technical guidance, strategic planning, and operational excellence solutions across all stages of spinning mill operations.

Greenfield Projects

- Preparation of detailed project reports

- Machinery selection and spin planning

- Plant layout and design

Operational Support

- Technical and operational troubleshooting

- Process optimization and efficiency enhancement

Modernization & Expansion

- Five-year strategic planning

- Capacity enhancement and plant shifting

- Value addition and process improvements

Process Engineering

- Process setup and optimization

- New yarn development

- Quality system setup

- Manpower planning

Maintenance & Training

- Maintenance audits and preventive maintenance systems

- Staff and workforce training

Cotton and Waste Recycling

- Implementation of recycling solutions

- Waste reduction and yield improvement

Fire & Safety

- Comprehensive fire and safety audits for spinning mills

Project Management Services

- Detailed project profiles and feasibility studies

- Plant & machinery selection

- Recruitment support for technical staff

- Technical guidance during installation & commissioning

- Support during trial production phase

Spinning Process Optimization

- Operational and process improvements

- Industry 4.0 automation solutions

- Benchmarking & best practice implementation

- Troubleshooting and root cause analysis

- First-grade yield improvement

- Raw material optimization and waste reduction

- Technical & maintenance audits of plant, machinery & utilities

- Implementation of preventive maintenance systems

- Cost control and profitability enhancement

- Quality systems setup, record keeping, and analytics

- Lead time reduction and flow reengineering

- New yarn and process development

Notable Projects & Clients

- Conifer Industries Pvt. Ltd. – 25,536 Spindles

- Jhanvai Spinning Pvt. Ltd. – 15,000 Spindles

- CC Projects (Arvind Ltd.) – 21 Tons/Day

- Vardhi Cotspin Pvt. Ltd. – 29,184 Spindles

- NTTL Ltd., Tanzania – 20,000 Spindles

- Bhaskar Industries Ltd. – Ring Denim Unit

- SMPS (Syntex) – Fire & Safety Audit

- Arvind Ltd. – Waste Recycling Plant

- Suryalakshmi Cotton Mills Ltd.

- Smart Recycling Solution